The original leadership team at Off Site was formed in 1985. The team is comprised of known leaders in the field of manufacturing engineering, flexible CNC manufacturing, assembly, and modern quality control and inspection technology. In 1992, a group of investors formed Off Site Manufacturing Technologies, Inc. (Off Site). This is how Off Site is known today.

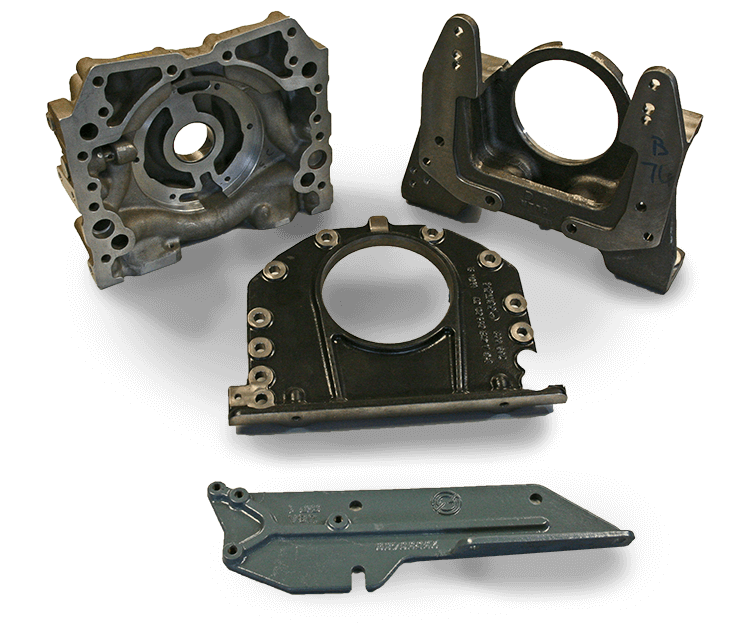

Off Site provides high quality, close tolerance machined parts made from a variety of materials including many grades of iron, steel, aluminum, and brass. Our entire team operates under a “quality first” methodology, ensuring we deliver parts free of any defect. Through ingenuity and flexibility Off Site is committed to building long term relationships with its customers by delivering top quality, prototype and production parts at stable and competitive pricing with the shortest lead times in the industry.

These “founding” accomplishments have enabled Off Site to grow substantially since its inception. Off Site’s success in flexible manufacturing and becoming a IATF 16949 registered supplier has resulted in awards of long term contracts with the heavy truck original equipment manufacturers (OEMs), the U.S. Government through defense contracts and a variety of Tier II and Tier III suppliers.

Off Site utilizes CNC equipment for its machining and manufacturing operations. Moreover, Off Site manufacturers rotating assemblies while attaining a high level of cost control. These controls extend into Off Sites offering of wet spray coating. This “in house” capability provides reduced lead times and high level of quality controls.

OFFsite manufacturing inc 50350 East Russell, Chesterfield, MI 48051 | T: 586.598.8850 |

Follow us on